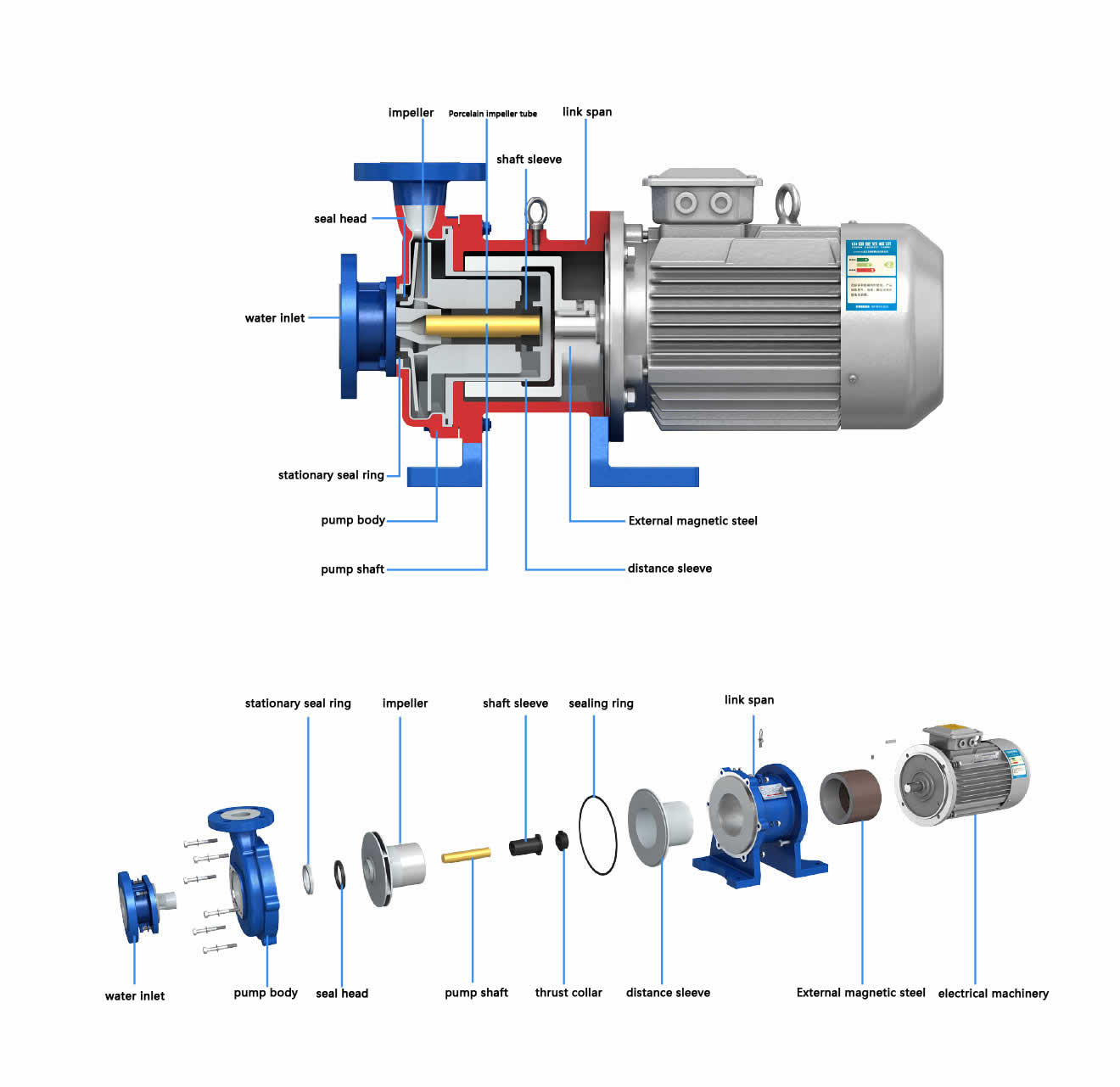

Product introduction

The flow part of the fluorine plastic magnetic drive pump is made of fluorine plastic alloy, which can continuously transport any concentration of acid, alkali, strong oxidant and other corrosive media. The shaft seal is cancelled and the magnetic coupling is used to drive indirectly, which eliminates the trouble of dripping and does not pollute the site. Fluorine plastic magnetic pump has the advantages of compact structure, beautiful appearance, small size, low noise and reliable operation

Instructions for use

· The magnetic pump should be installed horizontally, not erect, and the pump body should not bear the weight of the pipeline. For special occasions requiring vertical installation, the motor must face up.

· When the suction level is higher than the pump axis line, open the suction pipe valve before starting; if the suction level is lower than the pump axis line, the pipe shall be equipped with a bottom valve.

· The pump should be checked before use. The motor blade should rotate flexibly, without jamming and abnormal sound, and the fasteners should be fastened.

· Check whether the motor rotation direction is consistent with the steering mark of the magnetic pump.

· After the motor starts, slowly open the discharge valve. After the pump enters the normal working state, adjust the discharge valve to the required opening degree.

· Before the pump stops working, the discharge valve should be closed first and then the power supply should be cut off.

Scope of application

Saiken fluorine plastic magnetic pump is widely used in: biomedical, nuclear power thermoelectricity, paper printing and dyeing, pickling and polishing, fine chemical industry, pesticide medicine, electroplating wastewater, iron and steel metallurgy, petrochemical industry, corrosion resistant media can be used, such as: Sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, chloric acid, chromic acid, aqua aureus, acetic acid, formic acid, butyric acid, valeric acid, oleic acid, benzoic acid, oxygen water, hydroxide, bromine water, alkanes, ammonia (anhydrous), alcohols, aldehydes, ethers, iodine solution, benzene......

Model

Diameter(mm)

Power

Inlet

Outlet

SXP-400

40

40

5

1.05

150

8.5

0.4kw, 2HP

11.5

SXP-401

40

40

1.05

200

12

0.75kw, 2HP

18

SXP-422

50

40

1.2

200

18.5

1.5kw, 2HP

23

SXP-423

50

40

1.2

300

20.5

2.2kw, 2HP

25

SXP-425

50

40

1.0

400

25.5

3.7kw, 2HP

47

SXP-525

65

50

1.0

500

18.5

3.7kw, 2HP

48